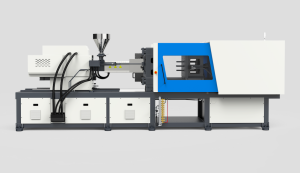

The desktop molding machine is an excellent tool for making plastic parts in the comfort of their home. It’s easy to use, and you can create some pretty cool things with a bit of practice. However, the machinery does require care and attention when using it so that you don’t damage your machine or hurt yourself! Here are some tips for maintaining a safe work environment while using your desktop molding machine:

Before the desktop molding machine is used

Before you start using your desktop molding machine, it’s essential to make sure that you have all the necessary parts. If something is missing, it can cause damage to your device and cause injury.

Next, check that the desktop molding machine is clean and dry. Dirt or moisture can affect how well it works and could cause potential problems if not addressed immediately after use.

Lastly, check that everything else seems in good working order: all buttons are working as expected; no lights are out or flashing; nothing looks damaged or broken (such as cracks around hinges).

Before working on a molding machine for the first time

Before you begin using a desktop molding machine for the first time, there are several essential things to check.

First and foremost, make sure that you know how to use it. If this is your first time using a desktop molding machine, it’s best if someone with experience can show you how they work. They should be able to answer any questions along the way (and maybe even give some tips).

Next up: make sure that all of your tools are in place! This includes having all of the suitable materials ready so that nothing falls through the cracks during production; having safety equipment like goggles or gloves if necessary; making sure everything else needed for production is also prepared (i.e., paper trays); and checking out any other specific requirements for working safely on this particular model before getting started (i.e., making sure air vents aren’t blocked).

Thirdly, ensure everything else related specifically towards getting started–like having an adequate workspace environment free from distractions–is taken care of so nothing gets overlooked when starting up production runs later down the line after initial setup has been completed successfully without issue.”

During use

Avoid touching the molding machine.

Do not leave the molding machine unattended.

Do not leave the molding machine near children or pets, as they may knock it over and hurt themselves if they are too close to it while in use.

If you have to set up your workstation near water, such as a sink or shower, make sure that there is no chance for any water from these sources to get into the electrical outlet that powers your desktop molding machine (e.g., by using an extension cord).

After use

Clean the machine.

Store it properly.

Take care of your hands and wrists: rest them after long periods of use, and use tools that help keep you comfortable while working on the computer.

Use a wrist rest or gel pad to cushion your hands, and position them at an angle between 45° and 90°. Use the mouse on a flat surface so that your wrist is straight.

Take care of your desktop molding machine for maximum safety and effectiveness

Clean your desktop molding machine regularly. Dust and dirt can get into its moving parts, causing them to malfunction over time.

Lubricate the molding machine’s cutting blades regularly with a light oil or lubricant like WD-40. This will keep them sharp and cut through materials smoothly without getting stuck or damaging the blade edges. It’s essential to maintain your desktop molding machine, so it doesn’t break down unexpectedly while being used on a project!

If you have children at home who are old enough to use power tools safely, make sure they don’t play with this one!

Finally, let’s summarize

We have covered the main points when using a desktop molding machine. It is important to remember that these machines are not toys, so you should always follow the instructions in your manual. Also, ensure that you have all the necessary safety equipment before starting work on your project!